Simple electric retrofit solutions, save up to 50% fuel consumption!

For traditional diesel engine-powered concrete mixer trucks, the biggest issue users face is that when the vehicle is stationary and the mixing drum is operating, a 150-300 kW diesel engine is used to drive a mixing drum that actually only requires 20-30 kW. This leads to extremely low diesel engine efficiency, along with significantly high fuel consumption and exhaust emissions. So, could there be a more innovative way to address this problem?

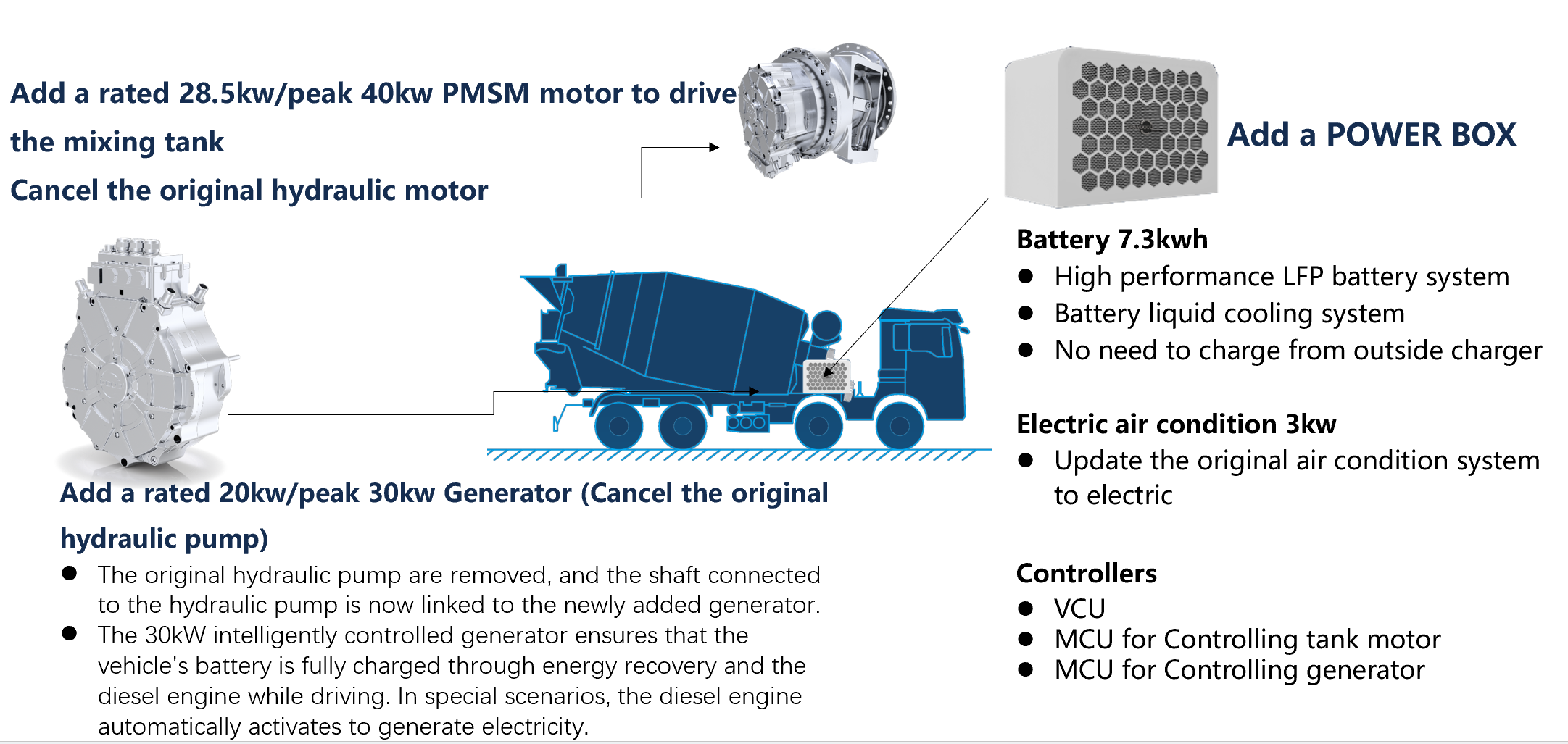

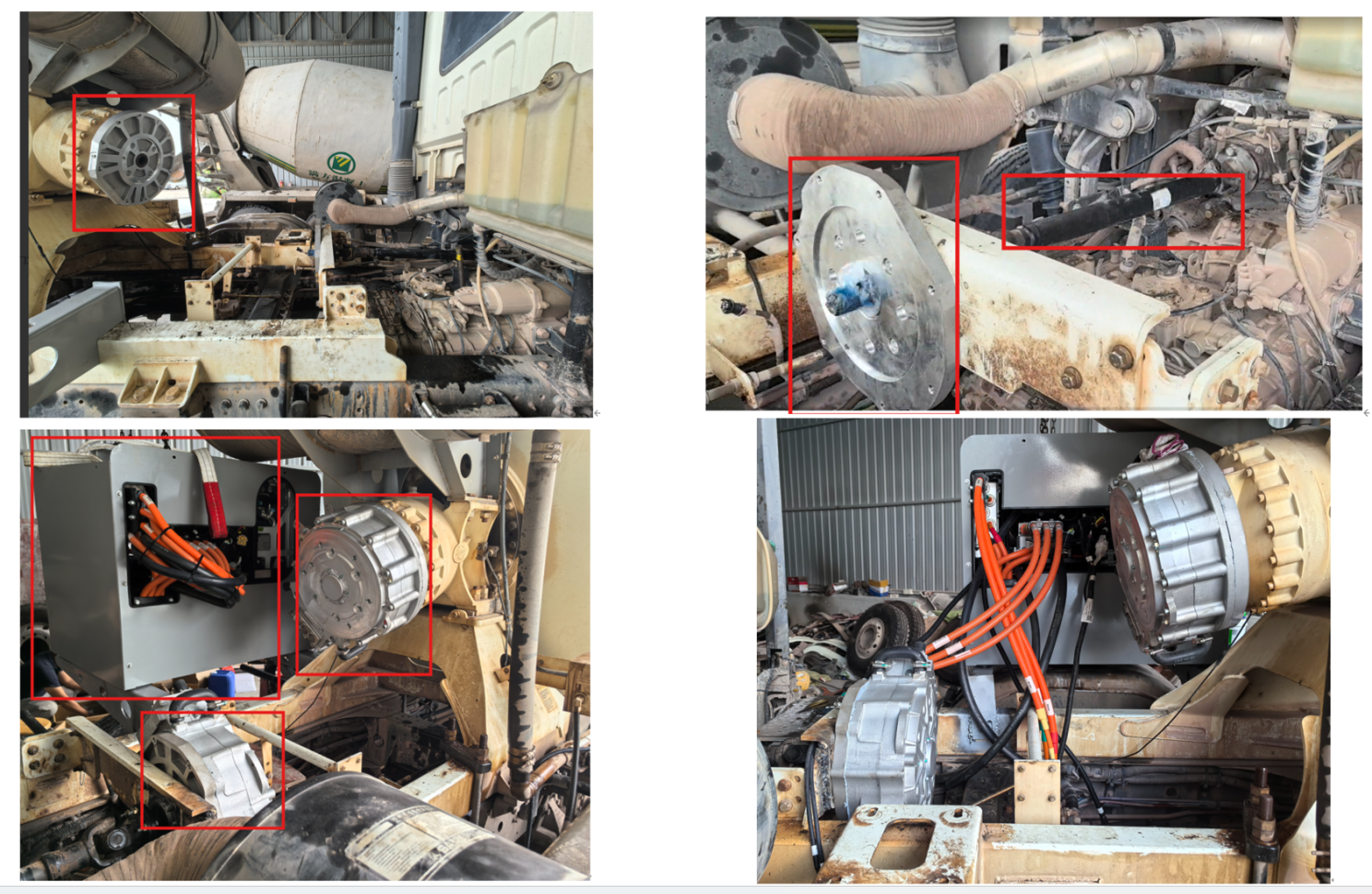

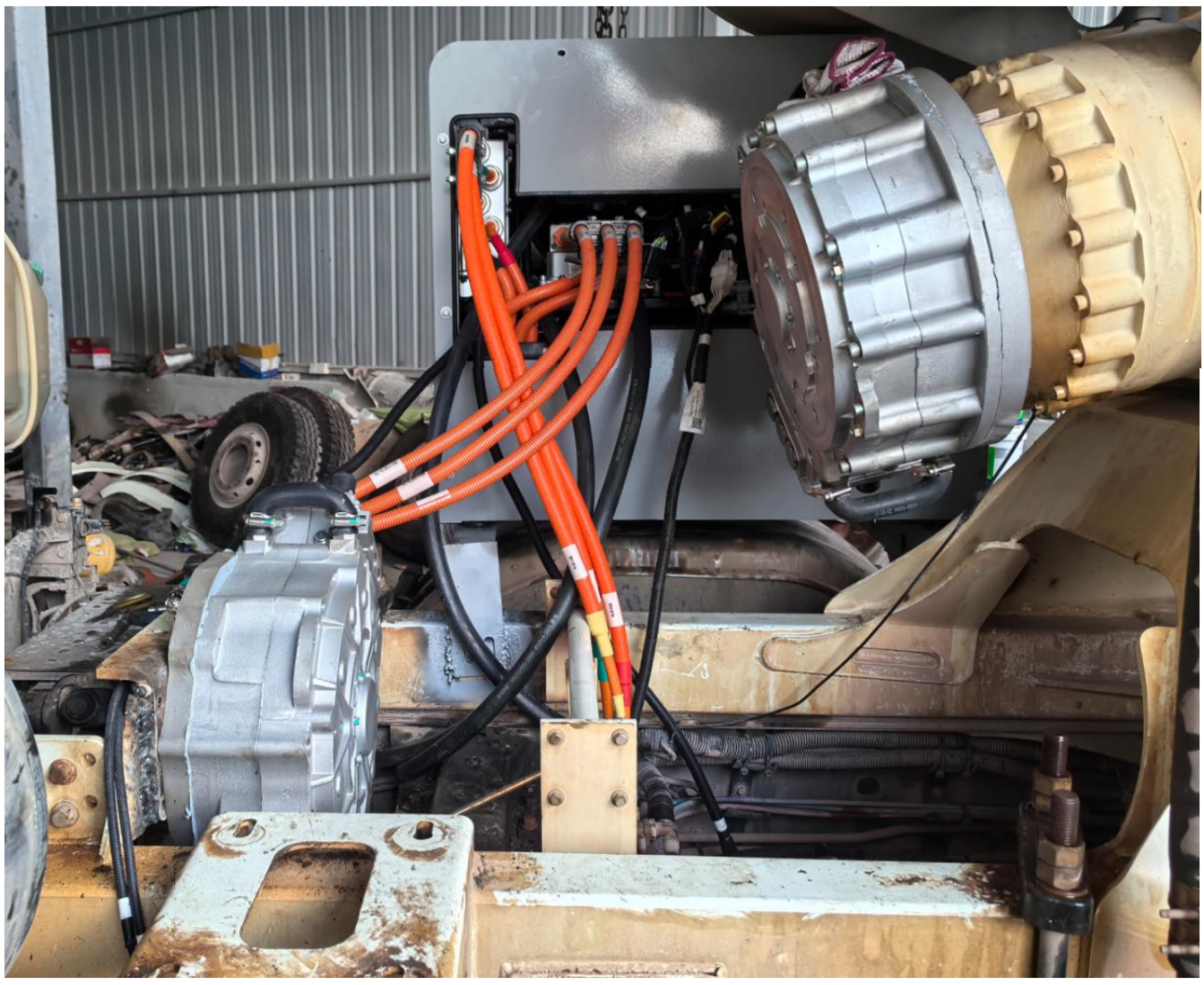

After two years of in-depth market research, customer usage analysis, and practical testing, ROYPOW has developed a simple yet intelligent fuel-to-electric retrofit system that makes vehicle electrification seamless. We replaced the traditional hydraulic drive system (hydraulic pump and motor) for the mixing drum with a permanent magnet synchronous generator and a permanent magnet synchronous drive motor, then configured a battery box for trucks, which contains a vehicle control unit (VCU), battery and management system, cooling system, and two motor controllers.

With the mixer truck electrification, the diesel engine drives the generator to charge the battery while the truck is driving. When the vehicle is parked and working, the engine stops, and the battery powers the motor (28 kW, with 3x starting torque) to drive the mixing drum. When the battery charge is low, the vehicle control unit (VCU) automatically starts the diesel engine to recharge it. Throughout the entire operation, no external charging stations are required, making it completely independent of charging infrastructure development.

Through the practical application of this electric retrofit system, we tested over 200 electric-retrofitted units at customer sites. By remotely collecting actual vehicle operation data, we found that the engine’s actual idle time is now about half of the total previous working time. This translates to approximately a 50% reduction in fuel consumption, demonstrating the strong performance of our electric retrofit solution. The installation of the entire electric retrofit system is also very straightforward—two workers can complete a vehicle electrification retrofit in at most one day.

This electric retrofit system has opened up significant market opportunities for ROYPOW. Beyond the Chinese market, we have already achieved bulk sales in Turkey and Georgia. Our goal is to promote the vehicle electrification of the superstructure work system without modifying the chassis. This approach avoids regulatory and certification requirements in many regions, allowing customers to adopt it quickly. With a small investment, they can achieve substantial savings in fuel costs, which aligns with our original intention. Of course, besides the mixer truck electrification, our next steps include the superstructure electrification for refrigerated trucks and municipal sanitation vehicles, providing electric retrofit solutions that genuinely solve customer problems.