LiFePO4 batteries are widely recognized as an ideal replacement for lead-acid batteries in electric forklifts due to their excellent thermal stability and safety profile. LFP chemistry has a higher decomposition temperature and presents a much lower risk of heat generation and oxygen release during internal short circuits or overcharging, thereby significantly reducing the likelihood of thermal runaway from the material level.

However, this inherent safety advantage does not mean thermal management can be overlooked. Under the demanding conditions of modern industrial logistics, batteries still inevitably generate substantial heat. If this heat accumulation can’t be effectively controlled, it directly degrades battery performance.

Why do forklift lithium batteries generate heat? How does prolonged overheating specifically damage them? And how does the ROYPOW air-cooled battery solution effectively tackle these challenges? This article will delve into these critical questions.

Why Do Forklift Lithium Batteries Generate Heat?

The heat generation in lithium forklift batteries is not caused by a single factor but is an inevitable result of the combined effect of their operating mode, usage environment, and cell chemistry.

1. High Load from Operating Patterns

(1) Frequent Start-Stop Operations and Acceleration

In warehouses, logistics hubs, or production lines, forklifts frequently start, accelerate, lift loads, brake, and reverse over short distances. The battery needs to deliver high current instantly during each operational cycle. During this process, the substantial internal Ohmic Heat is produced, rapidly raising the temperature.

(2) High-Power Continuous Discharge

When the forklift handles heavy loads or performs long-distance, high-intensity hauling, the motor requires the battery to supply energy continuously and under high load. Sustained high-power output means the battery is generating high heat over an extended period. If the heat dissipation efficiency cannot keep pace, the heat will continue to accumulate.

2. Harsh Operating Environment

In many regions (like the Middle East, Southeast Asia, Africa, and Latin America), warehouses and ports often face persistently high ambient temperatures, particularly in summer. As the temperature approaches or exceeds the optimal operating range of the electric forklift battery, its ability to dissipate heat drops significantly, raising its thermal equilibrium point.

In many forklifts, lithium batteries operate in relatively enclosed compartments with limited airflow. Heat generated during operation can become trapped in this confined space, leading to localized hot spots and reducing the natural dissipation of heat from the battery surface. Over time, this can result in a “heat accumulation effect,” where adjacent cells warm each other and the internal temperature of the compartment rises significantly above the ambient level.

3. Heat from Internal Resistance

All batteries possess internal resistance. According to Joule’s Law, when a high current flows through the battery’s internal resistance, it results in power loss, which is entirely converted into heat energy. Even the LFP forklift batteries will also continuously generate heat. This is a fundamental, ineliminable heating mechanism.

Impacts of Overheating on Forklift Lithium Batteries

When a LiFePO4 forklift battery operates under conditions that persistently exceed its suitable temperature range, a series of observable performance changes and potential risks will occur.

1. Shortened Cycle Life

High temperatures accelerate the degradation process of the battery’s internal materials. Specific manifestations include:

- Decomposition reactions of the electrolyte at the electrode interface, leading to irreversible consumption of active lithium ions.

- Changes in the crystal structure of the cathode material, resulting in a decline in the capacity retention rate.

- The rate of the battery’s overall capacity decay quickens as the number of cycles increases.

2. Degradation of Electrical Characteristics

Thermal stress alters the lithium battery’s electrochemical behavior, producing several measurable changes:

- A sharp rise in internal impedance directly reduces discharge efficiency.

- Lower and less stable voltage plateau, restricting the power output that the battery can deliver.

- Earlier voltage sag under identical load conditions, signaling impaired kinetic performance.

3. Heightened Safety Vulnerability

- Chronic exposure to elevated temperatures can break down the Solid Electrolyte Interphase (SEI). A deteriorated SEI layer exposes the anode to more aggressive reactions with the electrolyte, releasing additional heat.

- Excessive temperatures can also weaken the separator, increasing the risk of internal short circuits. Once direct contact occurs between the electrodes, localized heating can rapidly intensify, potentially escalating into thermal runaway.

4. Decline in Operational Efficiency

- When elevated temperatures are detected, the BMS automatically limits charging current or initiates pre-cooling procedures. This prolongs charging time and reduces equipment availability.

- Higher internal resistance translates into increased heat generation and reduced electrical conversion efficiency. Consequently, more energy is required to achieve the same workload, driving up energy consumption and operating costs.

5. Higher Maintenance Requirements

- More frequent inspections and servicing are required, as components age faster under thermal stress.

- The likelihood of system alerts or component faults increases, resulting in additional downtime and higher maintenance expenses.

These effects are interconnected; a decline in one aspect of performance can trigger issues in others.

ROYPOW Air-Cooled Forklift Lithium Batteries

Based on a deep understanding of the impact of high temperatures on battery performance and lifespan, ROYPOW delivers a systematic solution — air-cooled forklift lithium batteries engineered specifically for the practical demands of industrial equipment. They are well-suited for industrial and logistics applications in hot regions like the Middle East and Southeast Asia, where environmental adaptability, efficient cooling, and system simplicity are crucial for medium- and low-power, frequent start-stop operations.

Unlike approaches that primarily rely on housing dissipation, our air-cooled forklift lithium batteries utilize integrated fans working in concert with optimized air ducts. This synergy enables battery cells and core components to stay in a relatively balanced and stable temperature range. This design helps sustain stable output during prolonged high-power operation, slows capacity degradation, reduces thermal-runaway risks, enhances overall system safety, and lowers maintenance needs and operating costs.

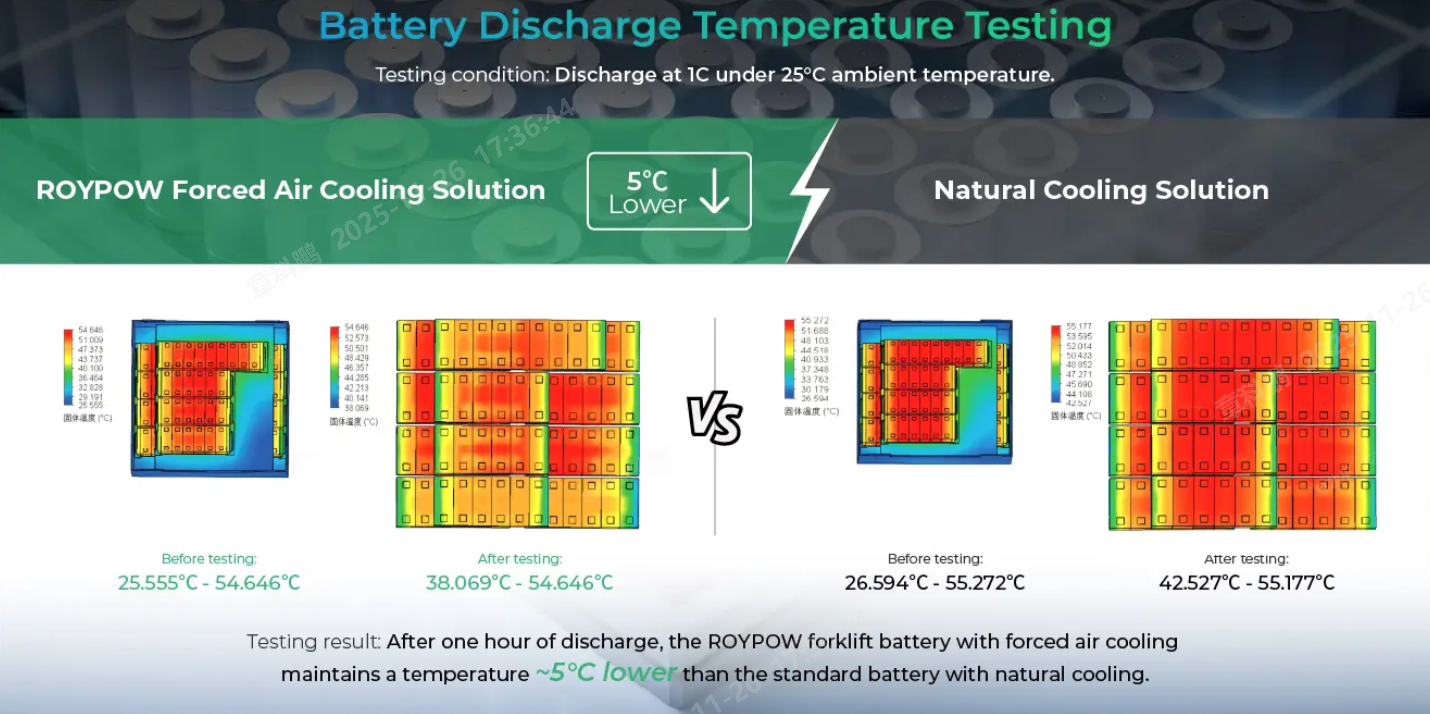

Test data confirms that under identical operating conditions (25°C ambient temperature, continuous 1C discharge for one hour), the air-cooling system maintains cell temperatures approximately 5°C lower than passive cooling solutions.

Apart from that, the forklift lithium battery is further characterized by the following:

- Utilizing Grade A LFP cells, it has a 10-year design life.

- The intelligent BMS continuously monitors temperature, voltage, current, and state of health.

- The integrated 4G module enables remote monitoring and real-time alerts.

- The built-in automatic fire suppression unit provides an extra layer of safety redundancy. This is particularly valuable in challenging settings such as high-temperature, dusty, or high-usage environments.

ROYPOW’s air-cooled forklift lithium batteries can be customized — from capacity and voltage configurations to form factors — to meet the specific operational requirements of industrial and logistics applications, optimizing performance, reliability, and safety.

Application of ROYPOW Air-Cooled Forklift Lithium Batteries

1. Cargo Handling Yards

In ports and logistics parks where equipment undergoes continuous high-intensity operation, air-cooled forklift lithium batteries effectively manage the substantial heat generated from sustained high-rate discharge.

2. Chemical Industry

Production environments often involve high ambient temperatures and strict safety requirements. In addition to the inherent stability of the LiFePO4 chemistry, our air-cooled batteries can also maintain low operating temperatures, providing dual safety assurance in risk-sensitive settings.

3. Cold Storage Operations

Frequent movement between cold storage and outdoor areas subjects batteries to sharp temperature shifts. These air-cooled forklift lithium batteries adapt quickly to thermal fluctuations, maintaining stable performance.

4. Steel Mills and Coal-Fired Power Plants

In hot, dusty industrial settings where passive cooling falls short, the forced convection in our air-cooled forklift lithium batteries ensures reliable operation under heavy loads.

These scenario involves high thermal load from both the environment and internal operation. Under such intense cooling pressure, ROYPOW air-cooling batteries showcase an indispensable active thermal management solution where passive methods are inadequate.

Future Trends: From Air Cooling to Liquid Cooling

Currently, for most conventional operating conditions, efficient air-cooling can effectively satisfy the thermal regulation requirements of forklift batteries. However, evolving industry trends are consistently driving the need for more advanced solutions:

- Warmer Operating Environments

- Increased Warehouse Density

- Extended Operating Hours

- High-Voltage and High-Capacity Models

Facing increasingly demanding application scenarios, liquid cooling technology shows high heat transfer efficiency, precise temperature control, and consistent thermal dissipation. That’s why at ROYPOW, we’re already building the next generation of liquid-cooled lithium forklift batteries to meet these future challenges head-on.

Ready to Improve Your Fleet’s Efficiency with ROYPOW?

If your operations are challenged by high temperatures, heavy workloads, or demanding multi-shift schedules, it’s time to upgrade your thermal management strategy.

Contact ROYPOW today. Whether with our robust air-cooling systems or the next-generation liquid cooling technology on the horizon, we are committed to powering the future of industrial logistics.