Most concrete mixer trucks in use today still rely on conventional diesel-powered hydraulic systems. As the global construction industry accelerates toward lower carbon emissions and sustainability, electrifying these vehicles is becoming increasingly important.

ROYPOW is leading the way in vehicle electrification with advanced electric retrofit solutions for mixer truck upper structures. These solutions help lower fuel consumption, reduce maintenance needs, and improve fleet operational efficiency, while delivering faster payback and supporting greener, more cost-effective construction operations.

Challenges of Conventional Hydraulic Upper-Structure Systems

Conventional concrete mixer trucks equipped with hydraulic upper-structure systems face several challenges:

- High idling time: Statistics show that idling accounts for 36–70% of operating hours. A typical 12–14 hour workday includes only 5–6 hours of actual driving.

- Excessive fuel consumption: Monitoring engine fuel injection indicates that a fully loaded 12 m³ mixer consumes 3.5–5.5 L of fuel per hour while idling.

- Frequent engine maintenance and reduced vehicle lifespan: Long periods of engine operation increase wear and maintenance requirements, driving up the operating costs.

- Poor fleet management: Each trip has different operating conditions, making fuel consumption difficult to track and manage effectively.

ROYPOW electric retrofit solutions are designed to address these challenges.

System Composition of ROYPOW Electric Retrofit Solutions

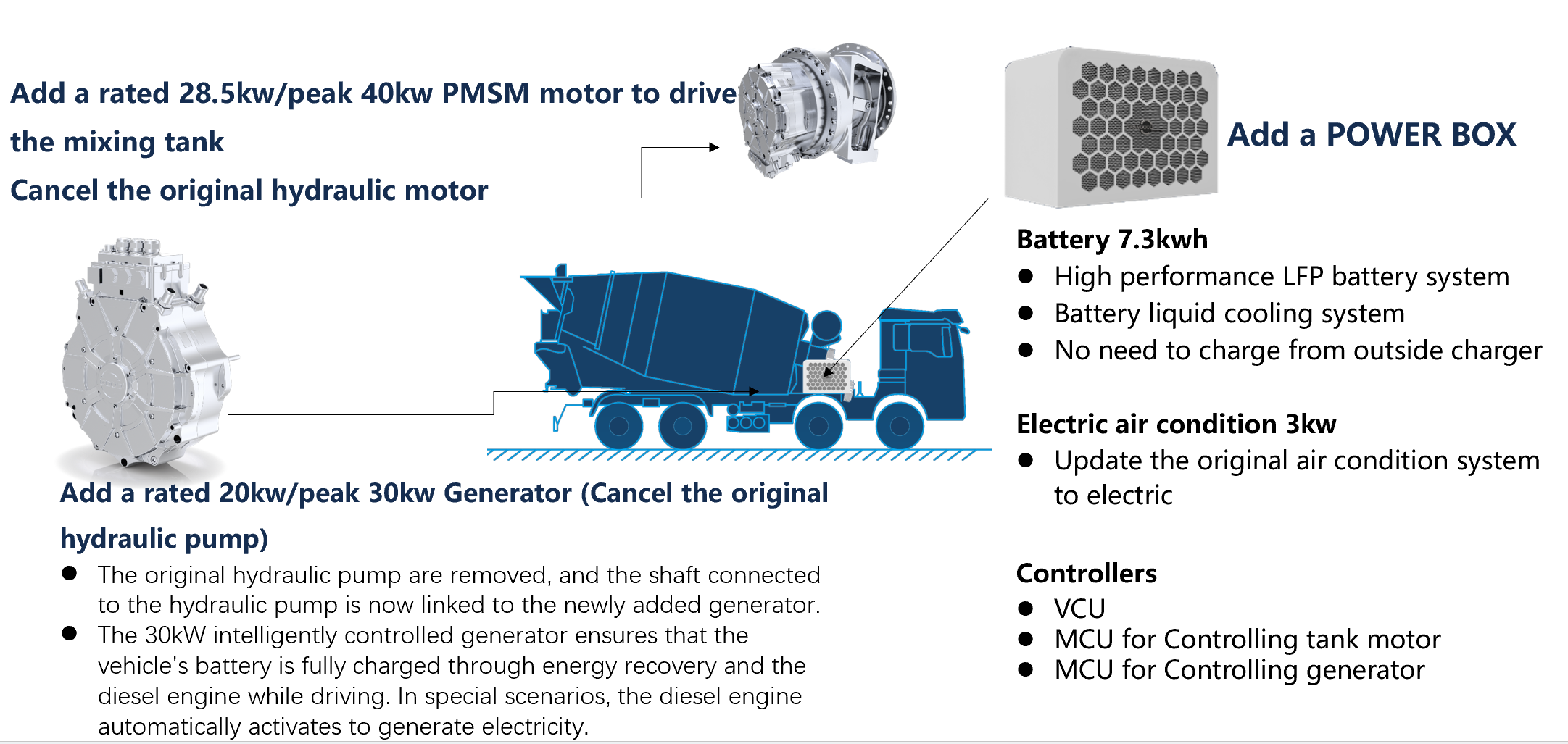

ROYPOW electric retrofit systems for concrete mixer trucks consist of the Upper-Structure Electric Drive System (including drive motor, generator, and power cabin), the Upper-Structure Control System (including central control panel and rear electric control lever), and the Digital Management Platform.

This vehicle electrification system replaces the traditional hydraulic upper-structure system by removing the hydraulic pump, hydraulic motor, hydraulic oil tank, fan, and associated hydraulic pipelines, while retaining the transmission shaft of the original hydraulic pump and the reducer to maintain mechanical linkage.

After the removal, the installation process involves mounting the drive motor and generator flanges, connecting the engine and generator via the existing transmission shaft, and installing the power cabin bracket, which requires welding and leveling for stability. The power cabin, drive motor, and generator are then securely installed, followed by connection of high- and low-voltage harnesses, cooling water pipes, and refrigerant lines. Finally, the central control system is integrated.

Features of ROYPOW Electric Retrofit Solutions

ROYPOW’s electric retrofit system is well-engineered with the following features:

- Lightweight and Efficient

Weighing 260 kg in total—only about 90 kg heavier than the conventional hydraulic system—without affecting vehicle payload.

- 7-in-1, Highly Integrated

The battery system, drive motor controller, generator controller, vehicle VCU, cooling system, air conditioning system, and DC-DC converter are highly integrated within the power cabin, simplifying installation and retrofit, improving system reliability, enhancing compatibility and versatility, and enabling easier maintenance and fleet management.

- Stable and Reliable

Main components are designed to meet strict automotive-grade standards, tested under rigorous and complex working conditions to ensure long-term stability and reliability.

- Wide Compatibility

Designed to work seamlessly with existing vehicle chassis, minimizing modification and downtime during installation.

- Intelligent Operations Management

The fleet management platform enables monitoring, quantification, and analysis of fuel-saving performance.

- Emergency-Ready

Compatible with conventional hydraulic rescue systems, allowing quick response without removing the drive motor.

Advantages of ROYPOW Electric Retrofit Solutions

By converting from diesel to electric power, the electrified concrete mixer trucks deliver:

For Regulatory Authorities

- Reduces carbon emissions by 30% and significantly lowers PM2.5 output.

- Decreases construction site noise complaints.

- Minimizes dust pollution through extended engine-off operation.

For Fleet Owners

- Saves fuel consumption by up to 30%. During driving, the drum is powered by the electric drive motor without additional engine fuel consumption, while extended engine-off operation during stops further reduces overall fuel use.

- Lowers maintenance costs, as the electric drive motor only requires periodic inspection, eliminating the need for hydraulic oil and reducing urea and maintenance expenses.

- Ensures consistent drum rotation during operation, lowering the risk of concrete segregation, reducing energy loss, and improving vehicle stability, especially when turning.

- Enhances better fleet management by enabling efficient scheduling, monitoring unloading, and improving overall vehicle utilization.

- Enjoys faster payback. Investment in the electric retrofit solution typically pays off within 8–12 months, thanks to fuel savings, reduced maintenance, and improved operational efficiency.

- Enjoys longer warranty coverage; while hydraulic systems typically have a one-year warranty, the electrified system comes with a three-year warranty for added peace of mind.

For Drivers

- Reduces noise levels below 65 dB, improving on-site comfort.

- Decoupled drive motor and engine power provide stronger performance under heavy loads, enhancing acceleration and hill-climbing capability.

- Air conditioning can run in summer without consuming fuel. Compared with traditional mechanical air conditioners, it delivers faster and efficient cooling.

ROYPOW Electric Retrofit Solutions in Action: Payback in 8 Months

In a recent deployment, a customer operating a fleet of over 1,000 SANY concrete mixer trucks adopted ROYPOW’s electric retrofit solution for 10 trucks to electrify their upper-structure systems.

After one month of operation, an electrified mixer truck logged 495.20 hours of drum operation and achieved 160.41 hours of engine-off time against an expected 233.92 hours, corresponding to a 68.57% engine-off ratio. This delivered cost savings of approximately RMB 7,300, with a projected payback period of around eight months.

The customer appreciated that the remote monitoring system offered real-time visibility into each vehicle’s daily operations via mobile devices, eliminating the need for on-site inspections and reducing labor effort for more efficient fleet management.

Looking ahead, ROYPOW continues to innovate and drive the electrification of concrete mixer trucks, enabling fleets to operate smarter, more efficiently, and more cost-effectively, while driving the construction industry toward greater sustainability.