Around the world, jobsites face universal challenges: unstable grids, extreme environments, strict noise regulations, and rising diesel costs. These hurdles are driving an increasing demand for reliable, adaptable, and sustainable power solutions. ROYPOW meets these challenges with Jobsite ESS solutions. In 2025, ROYPOW demonstrated that its energy solutions, engineered for rugged, high-demand applications, can deliver reliable power even in the most challenging environments.

PowerGo System: Reliable Mobile Power for Any Jobsite

Throughout 2025, ROYPOW PowerGo mobile energy storage systems were deployed across diverse jobsite environments—from urban construction sites, quietly powering tools, site offices, and temporary lighting as crews advanced floor by floor, to logistics yards and temporary facilities where grid access was limited and schedules could not wait.

Their ability to connect to a wide range of equipment, automatically start or stop generators for self-charging, and withstand frequent transportation made the PowerGo system a highly valuable option for rental applications. They also provided zero carbon emissions, up to 50% noise reduction, and reduced on-site maintenance. Across cities and regions, the PowerGo system consistently delivered reliable energy and became part of everyday jobsite operations—rolled in, connected, and relied upon.

PowerFusion System: Conquering Environmental Extremes from Icy Peaks to Scorching Deserts

At nearly 4,000 meters above sea level in the mountains of Tibet, ROYPOW PowerFusion hybrid energy storage systems supported construction activities at the Yajiang Hydropower Project. Thin air, extreme cold, lack of grid access, and heavy reliance on inefficient diesel generators—consuming up to approximately 633 gallons of fuel per day—made reliable energy supply critical at the site. Operating alongside generators, three PowerFusion systems delivered stable performance under these challenging conditions, while reducing diesel consumption by around 190 gallons per day, translating to 30–50% lower fuel use.

In Dubai, thousands of kilometers from Tibet, the PowerFusion systems were deployed at stadium and sports facility construction sites under extreme summer heat, where long working hours, high temperatures, and dust defined the environment. Designed to operate reliably across a wide temperature range from –20°C to 50°C, the same systems that performed in cold, high-altitude regions were seamlessly integrated into daily operations in extreme heat.

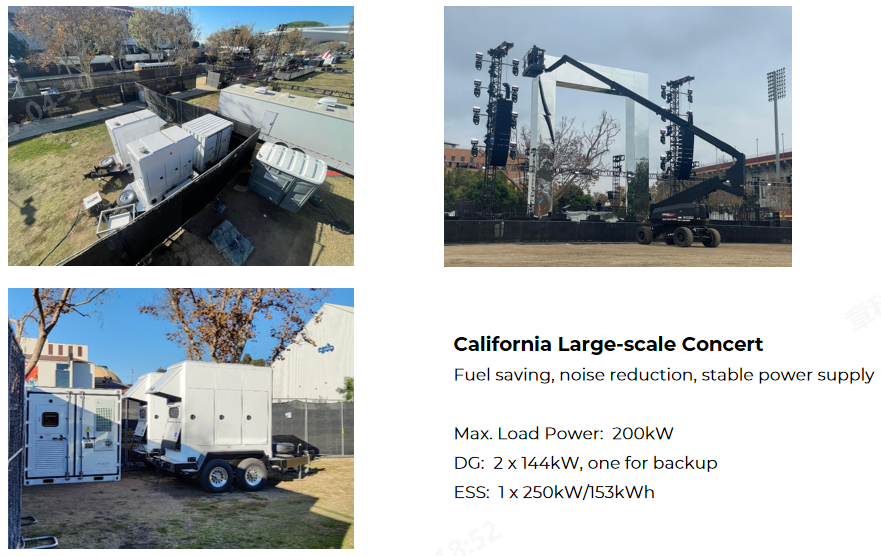

When outdoor concerts and live events in Los Angeles required energy storage systems to deliver stable, quiet power throughout performances, operating unobtrusively in the background, the PowerFusion systems played an important role, ensuring reliable energy for the entire event. Compared with diesel-only solutions, the hybrid setup significantly reduced fuel consumption and emissions.

In Sydney, ROYPOW Jobsite ESS solutions were deployed among cranes, scaffolding, and rising skylines, providing flexible temporary power as buildings took shape floor by floor. Meanwhile, in Johannesburg, the systems operated in mining environments, supporting industrial activities far from urban centers, where reliability was critical.

Conclusion 2025: Proven Value in the Field

Looking back at 2025, ROYPOW Jobsite ESS solutions proved their value across a wide range of environments, from deserts and mountains to urban worksites worldwide. At the heart of the successful real-world deployments is ROYPOW’s system integration expertise. By seamlessly bringing together advanced battery technologies, intelligent thermal management, smart battery monitoring, and multi-level safety control systems, ROYPOW delivers quick-to-deploy, field-ready Jobsite ESS solutions that help customers handle heavy workloads efficiently and safely, while minimizing downtime and operating costs.

Innovations in 2026: PowerBoost System

Looking ahead to 2026, a new chapter begins. ROYPOW is set to launch PowerBoost energy storage systems, engineered for high-power, inductive-load applications, supporting jobsites with heavier machinery and more demanding start-up requirements.